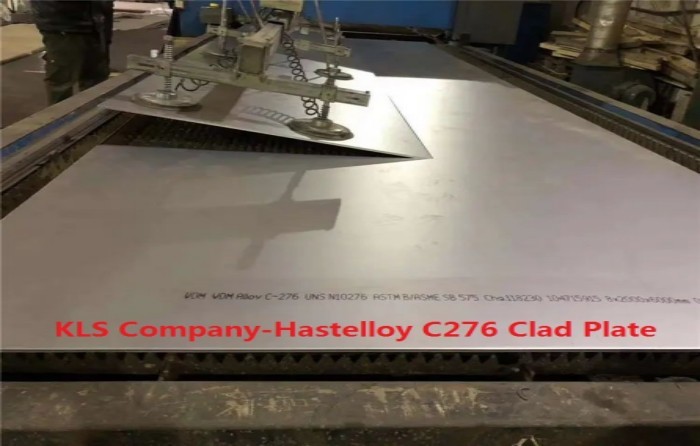

Hastelloy C276 Clad Plate: Unparalleled Corrosion Resistance and Strength

Introduction: Hastelloy C276 Clad Plate is a remarkable engineering material that combines the exceptional corrosion resistance of Hastelloy C276 alloy with the added strength and durability of a cladding layer. This innovative composite material has become a go-to choice in various industries where corrosion resistance, strength, and reliability are paramount.

Unmatched Corrosion Resistance: Hastelloy C276, the base material of the clad plate, is a nickel-molybdenum-chromium alloy renowned for its exceptional corrosion resistance. It exhibits remarkable resistance to a wide range of corrosive environments, including strong acids, pitting, crevice corrosion, and oxidizing and reducing atmospheres. This makes Hastelloy C276 Clad Plate ideal for applications in chemical processing, petrochemical, and oil and gas industries, where exposure to aggressive chemicals and corrosive substances is common. The base alloy's inherent resistance, combined with the protective cladding layer, ensures extended service life and reliability in the harshest operating conditions.

Superior Strength and Durability: Hastelloy C276 Clad Plate goes beyond exceptional corrosion resistance by providing remarkable strength and durability. The cladding layer, typically made of stainless steel or other high-strength alloys, adds an extra layer of mechanical strength to the base material. This composite structure enhances the plate's ability to withstand high pressures, mechanical stresses, and abrasive conditions. Consequently, it finds applications in critical equipment such as pressure vessels, heat exchangers, reactors, and pipelines, where both corrosion resistance and mechanical integrity are crucial.

The Art of Precision Machining: Exploring the Process of Graphite EDM

What is Cold Rolled Stainless Steel?

What are the advantages of finned tube?

Top 5 Industries Relying on Hot Dipped Galvanized Wire for Durability

Unveiling the Advantages of Choosing Aluminum Expanded Metal

How to Control the Quality of Micro Silica Fume?

Applications of High-Purity Metal Chromium

Versatile Applications: The versatility of Hastelloy C276 Clad Plate allows it to be used in a wide range of industries and applications. Its exceptional resistance to corrosion and aggressive chemicals makes it ideal for handling sulfuric acid, hydrochloric acid, phosphoric acid, and other highly corrosive substances. It finds extensive use in chemical processing plants, desalination plants, power generation facilities, pharmaceutical industries, and marine environments. Additionally, its ability to withstand high temperatures makes it suitable for applications in the aerospace and automotive sectors, where elevated temperatures and corrosive environments coexist.

Fabrication and Cost Considerations: Hastelloy C276 Clad Plate is designed to facilitate efficient fabrication and installation. The composite structure allows for ease of welding, cutting, and forming, providing flexibility during manufacturing processes. Furthermore, the use of clad plate eliminates the need for full-thickness applications, resulting in cost savings without compromising performance. By selecting the appropriate cladding material and thickness, the clad plate can be tailored to meet specific application requirements, ensuring optimal performance and cost-effectiveness.

Conclusion: Hastelloy C276 Clad Plate combines the exceptional corrosion resistance of Hastelloy C276 alloy with added strength and durability. This unique metal composite material offers unmatched performance in aggressive environments, making it an excellent choice for industries such as chemical processing, petrochemical, oil and gas, and more. Its versatility, ease of fabrication, and cost-effective nature further contribute to its widespread adoption across various applications.

What Are Advantages of Step-In Fence Posts?

How to Choose the Right Molybdenum Boat for Your Vacuum Deposition Application

The Most Common Super Alloy and Its Applications

Which is better galvanized or Galvalume?

What is the process of pre-galvanizing steel tube?

Durability Showdown: Are Fiberglass Screens Tougher than Aluminum Screens?

Are glass beads safe for sandblasting?