Alloy 904L Stainless Steel Pipe: A Versatile Solution for Demanding Applications

When it comes to selecting the right material for piping systems in demanding environments, Alloy 904L stainless steel stands out as an exceptional choice. Known for its superior corrosion resistance, high strength, and excellent weldability, Alloy 904L stainless steel pipes offer a versatile solution for a wide range of applications across various industries.

Alloy 904L is a low carbon, high alloy austenitic stainless steel that contains significant amounts of chromium, nickel, and molybdenum. This unique composition gives it remarkable resistance to corrosion from a wide range of aggressive media, including sulfuric acid, chloride solutions, and seawater. As a result, Alloy 904L stainless steel pipes are widely used in industries such as chemical processing, oil and gas, desalination plants, and pharmaceuticals, where corrosive environments are common.

One of the key advantages of Alloy 904L stainless steel pipes is their exceptional resistance to pitting and crevice corrosion. Pitting corrosion occurs when localized damage to the passive layer of stainless steel initiates corrosion in the form of small pits or holes. However, the high levels of chromium, nickel, and molybdenum in Alloy 904L provide robust protection against such corrosion, even in environments with high chloride concentrations. This makes Alloy 904L stainless steel pipes highly suitable for applications in coastal areas or industries where exposure to saltwater is prevalent.

Furthermore, Alloy 904L stainless steel pipes exhibit outstanding resistance to stress corrosion cracking (SCC). SCC is a type of corrosion that occurs under the combined influence of tensile stress and a corrosive environment, leading to catastrophic failures. However, Alloy 904L's unique composition imparts excellent resistance to SCC, ensuring the reliability and longevity of piping systems, even under high-stress conditions.

Explore more:What Are the Advantages of Steel Rails?

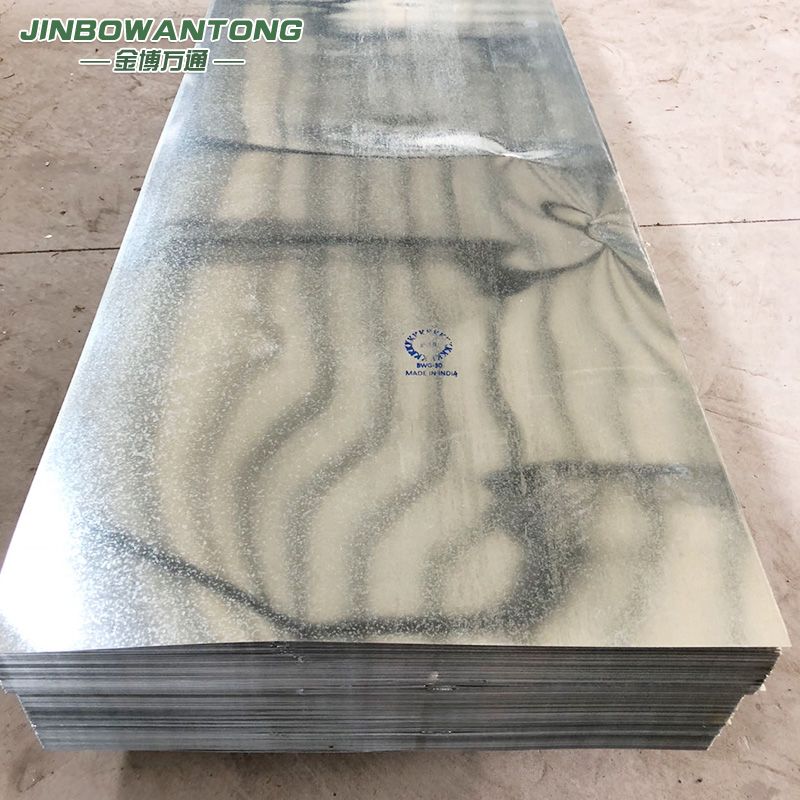

Hot-Dipped Galvanized Coil: Unleashing the Power of Corrosion Resistance

What are the applications of colored crushed glass?

Welded Wire Mesh Panel: Enhancing Strength and Security

Can Post Tensioning Be Used in Both New and Existing Structures?

How to use fiberglass filtration mesh for metal casting

What is Expanded Metal? A Versatile Solution for Diverse Applications

In addition to its corrosion resistance, Alloy 904L stainless steel pipes possess exceptional strength and toughness. They can withstand high-pressure environments and temperature variations, making them suitable for critical applications in oil and gas refineries, chemical plants, and power generation facilities. The high strength and resilience of Alloy 904L stainless steel pipes ensure the integrity of piping systems, minimizing the risk of leaks and ensuring the safety of operations.

Moreover, Alloy 904L stainless steel pipes are highly weldable and exhibit excellent forming properties. This allows for easy fabrication and installation, reducing time and labor costs. The weldability of Alloy 904L ensures that joints maintain the same level of corrosion resistance as the base material, making it an ideal choice for applications that require high-quality welds.

It is important to note that Alloy 904L stainless steel pipes come at a higher initial cost compared to standard stainless steels. However, considering their exceptional corrosion resistance and extended service life, they offer a cost-effective solution in the long run. The reduced maintenance and replacement costs associated with Alloy 904L stainless steel pipes make them an attractive option for industries that prioritize durability and reliability.

In conclusion, Alloy 904L stainless steel pipes provide a versatile and reliable solution for demanding applications. Their exceptional corrosion resistance, high strength, excellent weldability, and formability make them well-suited for industries that require robust and durable piping systems. Whether it is handling corrosive chemicals, transporting fluids in offshore environments, or operating in high-pressure and high-temperature conditions, Alloy 904L stainless steel pipes deliver outstanding performance, ensuring the smooth and efficient functioning of critical infrastructure.

Alloy C276 vs. Hastelloy C276: Understanding the Differences

What is nickel clad steel?

What Is Thermite Powder Used for?

The Versatility and Efficiency of Woven Mesh Filter Screens

Benefits and uses of perforated metal

The advantages of expanded metal mesh

What is the common problem of conveyor belt?