Ten Properties and Three Special Functions of Titanium

Titanium is an element with an atomic number of 22 in the periodic table. It is a subgroup element of the fourth period, that is, the IVB flag. In addition to titanium, this group of elements also includes zirconium and hafnium. Their common feature is a high melting point. Form a stable oxide film.

Ten properties of titanium

1. Low density, high strength and high specific strength

The density of titanium is 4.51g/cm3, which is 57% of steel. Titanium is less than twice heavier than aluminum and three times stronger than aluminum. The specific strength (strength/density ratio) of titanium alloy is the largest among commonly used industrial alloys. The specific strength of titanium alloy is 3.5 times that of stainless steel; 1.3 times that of aluminum alloy; and 1.7 times that of magnesium alloy, so it is essential for the aerospace industry. structural materials.

2. Excellent corrosion resistance

The passivity of titanium depends on the existence of an oxide film, and its corrosion resistance in oxidizing media is much better than that in reducing media. High rate corrosion occurs in reducing media. Titanium is not corroded in some corrosive media, such as seawater, wet chlorine, chlorite and hypochlorite solutions, nitric acid, chromic acid, metal chlorides, sulfides, and organic acids. However, in media that react with titanium to produce hydrogen (such as hydrochloric acid and sulfuric acid), titanium usually has a greater corrosion rate. However, if a small amount of oxidant is added to the acid, a passive film will be formed on the titanium surface. Therefore, titanium is corrosion-resistant in strong sulfuric acid-nitric acid or hydrochloric acid-nitric acid mixtures, and even in hydrochloric acid containing free chlorine. Titanium's protective oxide film often forms when the metal comes into contact with water, even in small amounts of water or water vapor. If titanium is exposed to a strong oxidizing environment without water at all, rapid oxidation will occur and violent reactions will occur, and spontaneous combustion often occurs. This phenomenon has occurred in the reaction of titanium with fuming nitric acid containing excess nitrogen oxide and with titanium and dry chlorine. Therefore, to prevent this type of reaction, a certain amount of moisture is necessary.

3. Good heat resistance

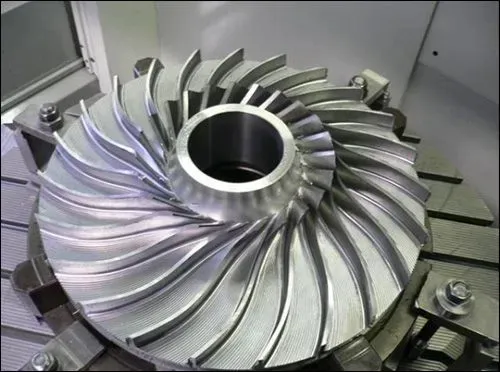

Generally, aluminum loses its original properties at 150℃ and stainless steel at 310℃, while titanium alloy still maintains good mechanical properties at about 500℃. When the aircraft speed reaches 2.7 times the speed of sound, the surface temperature of the aircraft structure reaches 230°C. Aluminum alloys and magnesium alloys can no longer be used, while titanium alloys can meet the requirements. Titanium has good heat resistance and is used in the discs and blades of aircraft engine compressors and the skin of the rear fuselage of aircraft.

4. Good low temperature performance

The strength of some titanium alloys (such as Ti-5AI-2.5SnELI) increases as the temperature decreases, but the plasticity does not decrease much. It still has good ductility and toughness at low temperatures and is suitable for use at ultra-low temperatures. It can be used in dry liquid hydrogen and liquid oxygen rocket engines, or as ultra-low temperature containers and storage tanks on manned spacecraft.

5. Non-magnetic

Titanium is non-magnetic. It is used in submarine shells and will not cause mine explosions.

6. Small thermal conductivity

The thermal conductivity of titanium is small, only 1/5 of steel, 1/13 of aluminum, and 1/25 of copper. Poor thermal conductivity is a disadvantage of titanium, but this feature of titanium can be exploited in certain situations.

7. Low elastic modulus

Titanium's elastic modulus is only 55% that of steel, which is a disadvantage when used as a structural material.

8. Tensile strength and yield strength are very close

The tensile strength of Ti-6AI-4V titanium alloy is 960MPa and the yield strength is 892MPa. The difference between the two is only 58MPa.

9. Titanium is easily oxidized at high temperatures

Titanium has a strong binding force with hydrogen and oxygen, so care should be taken to prevent oxidation and hydrogen absorption. Titanium welding should be carried out under argon gas protection to prevent contamination. Titanium tubes and sheets must be heat treated under vacuum, and the micro-oxidizing atmosphere must be controlled during heat treatment of titanium forgings.

10. Low damping resistance

Use titanium and other metal materials (copper, steel) to make bells of exactly the same shape and size. If you strike each bell with the same force, you will find that the sound lasts longer when the bell made of titanium oscillates, that is, through The energy given to the bell by striking is not easy to disappear, so we say that the damping performance of titanium is low.

Three special functions of titanium

1 Shape memory function

It refers to the ability of Ti-50% Ni (atomic) alloy to restore its original shape under certain temperature conditions. This material is called shape memory alloy.

2 superconducting function

It refers to NbTi alloy. When the temperature drops to close to absolute zero, wires made of NbTi alloy will lose resistance. If any large current passes through, the wire will not heat up and consume no energy. NbTi is called a superconducting material.

3 Hydrogen storage function

Refers to Ti-50%Fe (atomic) alloy, which has the ability to absorb large amounts of hydrogen. Using this characteristic of TiFe, hydrogen can be stored safely, that is, it is not necessary to use steel high-pressure gas cylinders to store hydrogen. Under certain conditions, TiFe can also release hydrogen. TiFe is called an energy storage material.

- Previous: Unlocking MMO Titanium Anode for Electrolytic Surface Treatment in 2024

- Next: None