How to Choose the Right Molybdenum Boat for Your Vacuum Deposition Application

Molybdenum boats are essential components in vacuum deposition processes, commonly used for evaporation and coating applications in various industries, including electronics, optics, and aerospace. Choosing the right molybdenum boat is crucial for achieving precise and efficient deposition. In this article, we will guide you through the steps to select the appropriate molybdenum boat for your specific vacuum deposition application.

1. Understand Your Application Requirements:

Before diving into the selection process, it's essential to have a clear understanding of your application's specific requirements. Consider factors such as the type of material to be evaporated, deposition method, desired film thickness, and the temperature and pressure conditions inside the vacuum chamber.

2. Material Purity:

Molybdenum boats come in various grades, with different levels of purity. The higher the purity, the better the boat will perform in terms of evaporation and resistance to contamination. For most applications, high-purity molybdenum (99.95% pure) is recommended.

3. Boat Dimensions:

The dimensions of the molybdenum boat should match your deposition setup and the size of the substrate or target. Consider the boat's length, width, and depth to ensure it can accommodate the required amount of material for deposition.

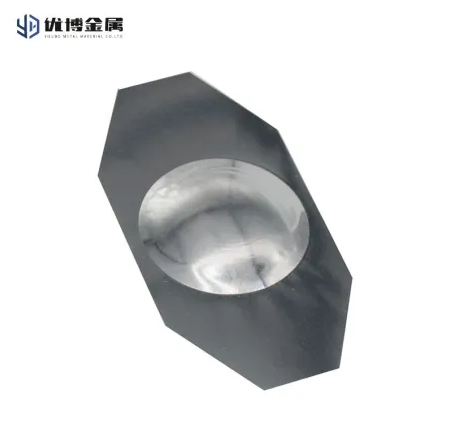

4. Boat Shape:

Molybdenum boats are available in various shapes, including flat-bottomed, V-shaped, and U-shaped. The choice of boat shape depends on the material's characteristics, the deposition method, and the desired film uniformity. V-shaped boats are often preferred for uniform and controlled evaporation.

5. Temperature Resistance:

Consider the maximum temperature your deposition process will reach. Molybdenum boats have excellent temperature resistance, but for extremely high-temperature applications, you may need boats made from higher melting point materials like tungsten.

6. Compatibility with Vacuum System:

Ensure that the selected molybdenum boat is compatible with your vacuum deposition system, including the boat's mounting options and connections. It should fit seamlessly into your setup without modification.

7. Handling and Loading Ease:

Consider the ease of loading and handling the molybdenum boat within your deposition system. Some boats come with features like pre-punched slots for secure filament placement or ease of material loading.

8. Longevity and Reusability:

If your application involves multiple deposition runs, you may want to choose a molybdenum boat known for its durability and reusability to reduce operational costs.

9. Cost Considerations:

While quality and performance are essential, it's also prudent to consider your budget constraints. Compare prices from reputable suppliers to find a molybdenum boat that offers the best balance of quality and affordability.

10. Seek Expert Advice:

If you are uncertain about which molybdenum boat to choose, consult with experts or suppliers who specialize in vacuum deposition equipment. They can provide valuable insights and recommendations based on your specific application needs.

Choosing the right molybdenum boat is a critical step in achieving precise and efficient vacuum deposition. By understanding your application requirements, considering material purity, boat dimensions, and compatibility with your vacuum system, you can select the ideal molybdenum boat for your deposition process. This careful selection will contribute to the quality and consistency of your deposited films, whether in semiconductor manufacturing, optical coatings, or other vacuum deposition applications.