Guidance of I-beam Structure and Their Types

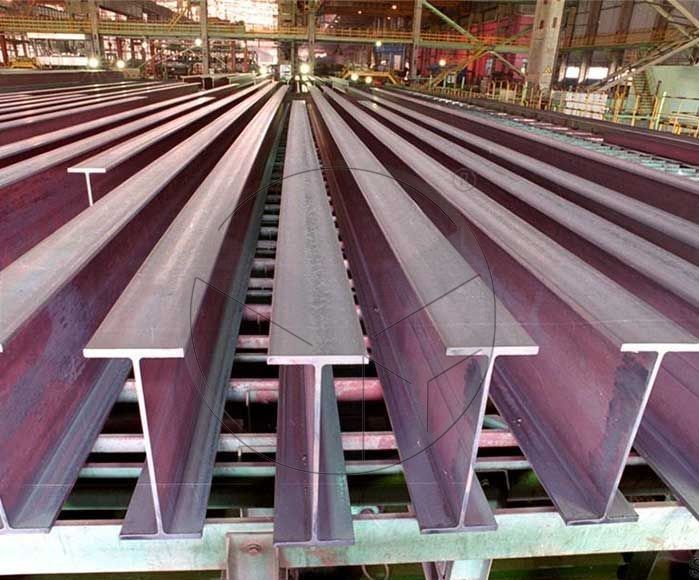

I-beam is a standard structural steel shape, which can be used as the key frame of various structures in the metal construction industry. For example, I-beams are used to build bridges, parking lots, skyscrapers, hospitals and so on. But what makes them such high-quality building materials?

Structural beam design

All structural beams have a basic design, including flanges (sometimes called legs) and webs (long vertical sections). The angle connecting the web and flange is called fillet.

Flat flanges at the top and bottom of the beam prevent bending, and the web can resist blunt forces. These components are designed to withstand the maximum bending load with as few materials as possible and form the foundation to support the high axle load.

All beams have depth, length and thickness. The depth of the beam is the distance from the top to the bottom. Width is the length of the horizontal flange. Thickness refers to the web and flange.

Types of I-beam

There are subtle differences between I-beams and beams that appear to have all the same characteristics, including H-Piles, universal beams (UB), W-beams, and wide flange beams. Although they all have I-shaped cross sections and the word "general" implies its wide use, there are still some noteworthy nuances.

I-beam

I-beams have parallel flanges. Sometimes these flanges taper off. The legs on I-beams are narrower than those on H-Piles and W-beams / wide flange beams. As a result, they can withstand lighter weight and provide shorter lengths - up to 100 feet, while H-Piles and W-beams can span up to 330 feet. I beam is a kind of s beam.

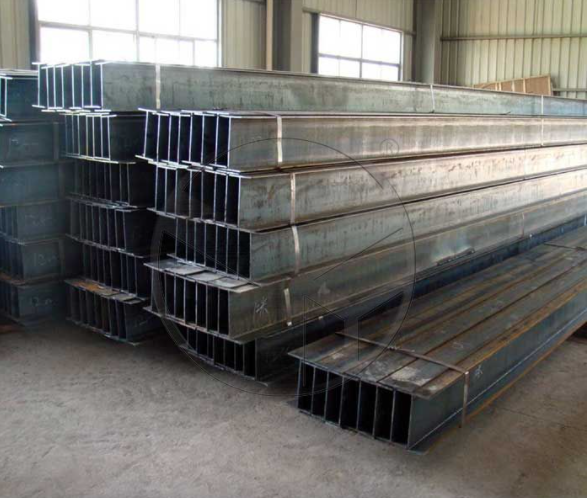

H-shaped pile

H-Piles are also called load-bearing piles. They look almost the same as I-beams, but they are heavier. They all have parallel flange faces, but H-Piles have wider legs. Importantly, H-Piles are designed to have the same thickness in all parts of the beam, so they can withstand greater vertical loads. H-beam is a kind of wide flange beam.

Explore more:How about stainless steel window screens?

What is the difference between uns N07718 and Inconel 625?

What is the purpose of gabions box?

Nickel Base Alloy: A Versatile and Durable Metal for Modern Applications

Choosing the Right Mesh Filters: Factors to Consider

What is the difference between Galvalume and galvanized steel?

what is nichrome wire used for?

W-beam

Similar to H-Piles, W-beams have wider legs than standard I-beams. However, they do not necessarily have the same web and flange thickness.

Different metal I-beam

Although I-beams are standard structural steel shapes, they can also be used as aluminum beams. The most common general aluminum metal grade used for beams is 6061 aluminum beams. The beam is also made of stainless steel

What is a beam support?

Beam supports are additional components that provide safer and more versatile building materials. For example, they can allow beams to be connected to other beams, connect beams to other structural steel products, concentrate loads by evenly distributing weight, add cranes and other overhead equipment, or connect wires to hang lighting and other lightweight materials.

They can be connected to the beam by various mechanisms, such as clips, screws, threads and press fit. The beam support can also be installed at different positions of the beam, which can be installed at the bottom, top or bottom center. I-beam fixture is one of the most popular beam supports.

You can also check yongyang website to learn more about other structural steel product types, common applications and railway rails. Welcome to contact us.

How Do You Specify a Reducing Tee?

The Art of Precision Machining: Exploring the Process of Graphite EDM

What is Cold Rolled Stainless Steel?

What are the advantages of finned tube?

Top 5 Industries Relying on Hot Dipped Galvanized Wire for Durability

Unveiling the Advantages of Choosing Aluminum Expanded Metal

How to Control the Quality of Micro Silica Fume?